Schumacher cutting system for John Deere headers

12/02/2025

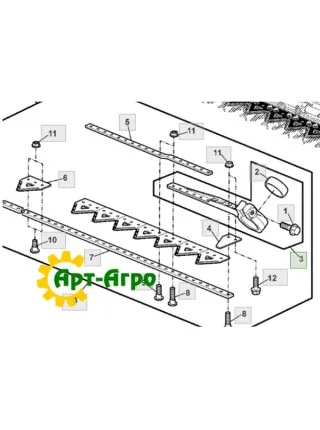

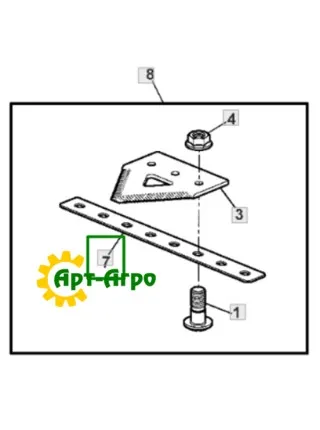

The Schumacher cutting system is one of the most efficient cutting systems used on John Deere headers. Thanks to its unique design and high-quality materials, it ensures high performance and reliability under various harvesting conditions.

Features and Benefits of the Schumacher System

-

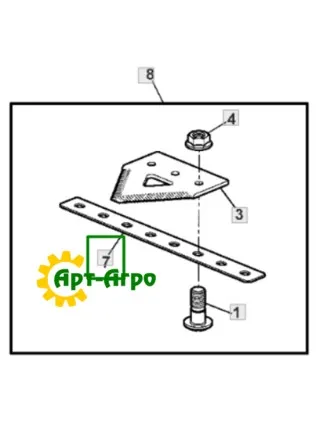

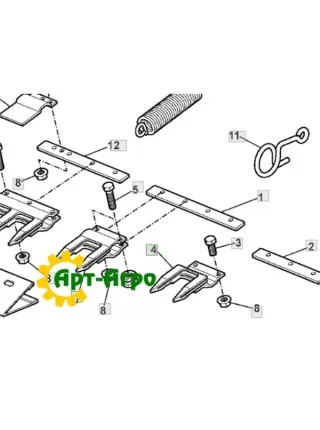

Modular Design

The Schumacher system has a modular design, making it easy to replace individual components without the need for complete disassembly. -

Precision Knife Sharpening

Special sharpening of the cutting segments allows for a clean and fast cut, even at high operating speeds of the header. -

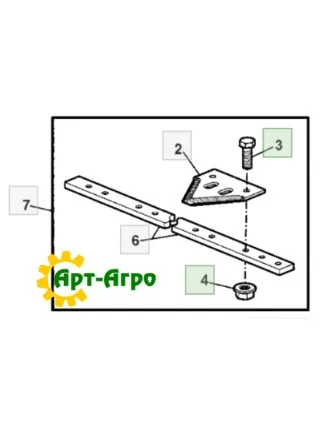

Double-Edged Knife Segments

The cutting segments have double-sided sharpening, which extends the system's lifespan and reduces maintenance costs. -

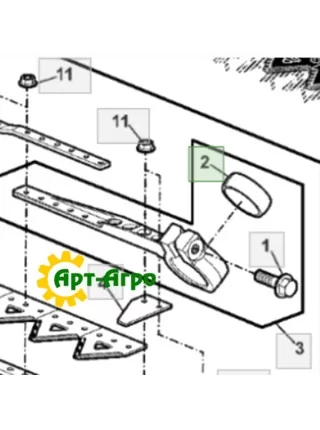

Specially Shaped Fingers

The unique design of the guiding fingers prevents clogging and reduces crop losses during harvesting. -

Minimal Vibrations

Thanks to its balanced design, the system operates with minimal vibrations, reducing stress on the header and improving working comfort. -

Energy Efficiency

The Schumacher system requires less effort to operate, reducing drive load and saving fuel.

Application and Reliability

The Schumacher cutting system is used on many models of John Deere headers and other agricultural machines. It is particularly effective for harvesting grain crops, providing precise and even cuts even in challenging weather conditions. The high wear resistance of components and ease of replacement make this system an optimal choice for farmers and agricultural enterprises.

Conclusion

Using the Schumacher cutting system on John Deere headers guarantees high efficiency and reliability during the harvesting season. Thanks to innovative solutions and quality materials, this system minimizes crop losses and increases the productivity of agricultural machinery.

Recommended products

The Schumacher cutting system is one of the most efficient cutting systems used on John Deere headers. Thanks to its unique design and high-quality materials, it ensures high performance and reliability under various harvesting conditions.

Features and Benefits of the Schumacher System

-

Modular Design

The Schumacher system has a modular design, making it easy to replace individual components without the need for complete disassembly. -

Precision Knife Sharpening

Special sharpening of the cutting segments allows for a clean and fast cut, even at high operating speeds of the header. -

Double-Edged Knife Segments

The cutting segments have double-sided sharpening, which extends the system's lifespan and reduces maintenance costs. -

Specially Shaped Fingers

The unique design of the guiding fingers prevents clogging and reduces crop losses during harvesting. -

Minimal Vibrations

Thanks to its balanced design, the system operates with minimal vibrations, reducing stress on the header and improving working comfort. -

Energy Efficiency

The Schumacher system requires less effort to operate, reducing drive load and saving fuel.

Application and Reliability

The Schumacher cutting system is used on many models of John Deere headers and other agricultural machines. It is particularly effective for harvesting grain crops, providing precise and even cuts even in challenging weather conditions. The high wear resistance of components and ease of replacement make this system an optimal choice for farmers and agricultural enterprises.

Conclusion

Using the Schumacher cutting system on John Deere headers guarantees high efficiency and reliability during the harvesting season. Thanks to innovative solutions and quality materials, this system minimizes crop losses and increases the productivity of agricultural machinery.

The Schumacher cutting system is one of the most efficient cutting systems used on John Deere headers. Thanks to its unique design and high-quality materials, it ensures high performance and reliability under various harvesting conditions.

Features and Benefits of the Schumacher System

-

Modular Design

The Schumacher system has a modular design, making it easy to replace individual components without the need for complete disassembly. -

Precision Knife Sharpening

Special sharpening of the cutting segments allows for a clean and fast cut, even at high operating speeds of the header. -

Double-Edged Knife Segments

The cutting segments have double-sided sharpening, which extends the system's lifespan and reduces maintenance costs. -

Specially Shaped Fingers

The unique design of the guiding fingers prevents clogging and reduces crop losses during harvesting. -

Minimal Vibrations

Thanks to its balanced design, the system operates with minimal vibrations, reducing stress on the header and improving working comfort. -

Energy Efficiency

The Schumacher system requires less effort to operate, reducing drive load and saving fuel.

Application and Reliability

The Schumacher cutting system is used on many models of John Deere headers and other agricultural machines. It is particularly effective for harvesting grain crops, providing precise and even cuts even in challenging weather conditions. The high wear resistance of components and ease of replacement make this system an optimal choice for farmers and agricultural enterprises.

Conclusion

Using the Schumacher cutting system on John Deere headers guarantees high efficiency and reliability during the harvesting season. Thanks to innovative solutions and quality materials, this system minimizes crop losses and increases the productivity of agricultural machinery.

The Schumacher cutting system is one of the most efficient cutting systems used on John Deere headers. Thanks to its unique design and high-quality materials, it ensures high performance and reliability under various harvesting conditions.

Features and Benefits of the Schumacher System

-

Modular Design

The Schumacher system has a modular design, making it easy to replace individual components without the need for complete disassembly. -

Precision Knife Sharpening

Special sharpening of the cutting segments allows for a clean and fast cut, even at high operating speeds of the header. -

Double-Edged Knife Segments

The cutting segments have double-sided sharpening, which extends the system's lifespan and reduces maintenance costs. -

Specially Shaped Fingers

The unique design of the guiding fingers prevents clogging and reduces crop losses during harvesting. -

Minimal Vibrations

Thanks to its balanced design, the system operates with minimal vibrations, reducing stress on the header and improving working comfort. -

Energy Efficiency

The Schumacher system requires less effort to operate, reducing drive load and saving fuel.

Application and Reliability

The Schumacher cutting system is used on many models of John Deere headers and other agricultural machines. It is particularly effective for harvesting grain crops, providing precise and even cuts even in challenging weather conditions. The high wear resistance of components and ease of replacement make this system an optimal choice for farmers and agricultural enterprises.

Conclusion

Using the Schumacher cutting system on John Deere headers guarantees high efficiency and reliability during the harvesting season. Thanks to innovative solutions and quality materials, this system minimizes crop losses and increases the productivity of agricultural machinery.

The Schumacher cutting system is one of the most efficient cutting systems used on John Deere headers. Thanks to its unique design and high-quality materials, it ensures high performance and reliability under various harvesting conditions.

Features and Benefits of the Schumacher System

-

Modular Design

The Schumacher system has a modular design, making it easy to replace individual components without the need for complete disassembly. -

Precision Knife Sharpening

Special sharpening of the cutting segments allows for a clean and fast cut, even at high operating speeds of the header. -

Double-Edged Knife Segments

The cutting segments have double-sided sharpening, which extends the system's lifespan and reduces maintenance costs. -

Specially Shaped Fingers

The unique design of the guiding fingers prevents clogging and reduces crop losses during harvesting. -

Minimal Vibrations

Thanks to its balanced design, the system operates with minimal vibrations, reducing stress on the header and improving working comfort. -

Energy Efficiency

The Schumacher system requires less effort to operate, reducing drive load and saving fuel.

Application and Reliability

The Schumacher cutting system is used on many models of John Deere headers and other agricultural machines. It is particularly effective for harvesting grain crops, providing precise and even cuts even in challenging weather conditions. The high wear resistance of components and ease of replacement make this system an optimal choice for farmers and agricultural enterprises.

Conclusion

Using the Schumacher cutting system on John Deere headers guarantees high efficiency and reliability during the harvesting season. Thanks to innovative solutions and quality materials, this system minimizes crop losses and increases the productivity of agricultural machinery.

The Schumacher cutting system is one of the most efficient cutting systems used on John Deere headers. Thanks to its unique design and high-quality materials, it ensures high performance and reliability under various harvesting conditions.

Features and Benefits of the Schumacher System

-

Modular Design

The Schumacher system has a modular design, making it easy to replace individual components without the need for complete disassembly. -

Precision Knife Sharpening

Special sharpening of the cutting segments allows for a clean and fast cut, even at high operating speeds of the header. -

Double-Edged Knife Segments

The cutting segments have double-sided sharpening, which extends the system's lifespan and reduces maintenance costs. -

Specially Shaped Fingers

The unique design of the guiding fingers prevents clogging and reduces crop losses during harvesting. -

Minimal Vibrations

Thanks to its balanced design, the system operates with minimal vibrations, reducing stress on the header and improving working comfort. -

Energy Efficiency

The Schumacher system requires less effort to operate, reducing drive load and saving fuel.

Application and Reliability

The Schumacher cutting system is used on many models of John Deere headers and other agricultural machines. It is particularly effective for harvesting grain crops, providing precise and even cuts even in challenging weather conditions. The high wear resistance of components and ease of replacement make this system an optimal choice for farmers and agricultural enterprises.

Conclusion

Using the Schumacher cutting system on John Deere headers guarantees high efficiency and reliability during the harvesting season. Thanks to innovative solutions and quality materials, this system minimizes crop losses and increases the productivity of agricultural machinery.

The Schumacher cutting system is one of the most efficient cutting systems used on John Deere headers. Thanks to its unique design and high-quality materials, it ensures high performance and reliability under various harvesting conditions.

Features and Benefits of the Schumacher System

-

Modular Design

The Schumacher system has a modular design, making it easy to replace individual components without the need for complete disassembly. -

Precision Knife Sharpening

Special sharpening of the cutting segments allows for a clean and fast cut, even at high operating speeds of the header. -

Double-Edged Knife Segments

The cutting segments have double-sided sharpening, which extends the system's lifespan and reduces maintenance costs. -

Specially Shaped Fingers

The unique design of the guiding fingers prevents clogging and reduces crop losses during harvesting. -

Minimal Vibrations

Thanks to its balanced design, the system operates with minimal vibrations, reducing stress on the header and improving working comfort. -

Energy Efficiency

The Schumacher system requires less effort to operate, reducing drive load and saving fuel.

Application and Reliability

The Schumacher cutting system is used on many models of John Deere headers and other agricultural machines. It is particularly effective for harvesting grain crops, providing precise and even cuts even in challenging weather conditions. The high wear resistance of components and ease of replacement make this system an optimal choice for farmers and agricultural enterprises.

Conclusion

Using the Schumacher cutting system on John Deere headers guarantees high efficiency and reliability during the harvesting season. Thanks to innovative solutions and quality materials, this system minimizes crop losses and increases the productivity of agricultural machinery.

The Schumacher cutting system is one of the most efficient cutting systems used on John Deere headers. Thanks to its unique design and high-quality materials, it ensures high performance and reliability under various harvesting conditions.

Features and Benefits of the Schumacher System

-

Modular Design

The Schumacher system has a modular design, making it easy to replace individual components without the need for complete disassembly. -

Precision Knife Sharpening

Special sharpening of the cutting segments allows for a clean and fast cut, even at high operating speeds of the header. -

Double-Edged Knife Segments

The cutting segments have double-sided sharpening, which extends the system's lifespan and reduces maintenance costs. -

Specially Shaped Fingers

The unique design of the guiding fingers prevents clogging and reduces crop losses during harvesting. -

Minimal Vibrations

Thanks to its balanced design, the system operates with minimal vibrations, reducing stress on the header and improving working comfort. -

Energy Efficiency

The Schumacher system requires less effort to operate, reducing drive load and saving fuel.

Application and Reliability

The Schumacher cutting system is used on many models of John Deere headers and other agricultural machines. It is particularly effective for harvesting grain crops, providing precise and even cuts even in challenging weather conditions. The high wear resistance of components and ease of replacement make this system an optimal choice for farmers and agricultural enterprises.

Conclusion

Using the Schumacher cutting system on John Deere headers guarantees high efficiency and reliability during the harvesting season. Thanks to innovative solutions and quality materials, this system minimizes crop losses and increases the productivity of agricultural machinery.

The Schumacher cutting system is one of the most efficient cutting systems used on John Deere headers. Thanks to its unique design and high-quality materials, it ensures high performance and reliability under various harvesting conditions.

Features and Benefits of the Schumacher System

-

Modular Design

The Schumacher system has a modular design, making it easy to replace individual components without the need for complete disassembly. -

Precision Knife Sharpening

Special sharpening of the cutting segments allows for a clean and fast cut, even at high operating speeds of the header. -

Double-Edged Knife Segments

The cutting segments have double-sided sharpening, which extends the system's lifespan and reduces maintenance costs. -

Specially Shaped Fingers

The unique design of the guiding fingers prevents clogging and reduces crop losses during harvesting. -

Minimal Vibrations

Thanks to its balanced design, the system operates with minimal vibrations, reducing stress on the header and improving working comfort. -

Energy Efficiency

The Schumacher system requires less effort to operate, reducing drive load and saving fuel.

Application and Reliability

The Schumacher cutting system is used on many models of John Deere headers and other agricultural machines. It is particularly effective for harvesting grain crops, providing precise and even cuts even in challenging weather conditions. The high wear resistance of components and ease of replacement make this system an optimal choice for farmers and agricultural enterprises.

Conclusion

Using the Schumacher cutting system on John Deere headers guarantees high efficiency and reliability during the harvesting season. Thanks to innovative solutions and quality materials, this system minimizes crop losses and increases the productivity of agricultural machinery.