How to choose a nozzle for an obpriskuvach

18/06/2020

How to choose and buy nozzles for sprayers? What nuances need to be taken into account? What types of nozzles are on the market? This is detailed in the article.

Why are injectors needed?

Agricultural sprayers are primarily used for precise spraying of water, necessary biological products and various solutions for pest, disease, weed control or plant nutrition.

In order for the solutions to accurately hit the desired surfaces and to save the amount of liquid, special devices were invented - nozzles.

During operation, the solution passes through the body of the nozzle, is sent to a special reservoir, where it is saturated with air. Weighted droplets are not blown away so quickly by the wind, falling on the planned area of green spaces. This significantly increases the efficiency of crop treatment, there is no need to additionally increase the concentration of chemical solutions or re-treat the plants.

Spray nozzles - types

Before purchasing the nozzles you need, you need to understand their types. Based on the design, they are divided by the number of heads:

- - single;

- - triple;

- - quadruple;

- - five.

Happen with one or two exits for connection to system. The atomizer itself at the nozzle can also be equipped with an applicator, for greater savings.

The so-called injector nozzles equipped with air blowing are best suited for large volumes. Experts recommend purchasing them for cars with large tanks. Then it becomes possible to work longer in the field, not to return to the gas station again.

How to choose nozzles

The point of spraying is to ensure that everything we pour into the tank hits the target surface.

Nozzles, like various other parts of the sprayer, it is important to select based on the type and model of the unit. The correct choice will significantly affect the overall efficiency of your equipment. The choice of nozzles depends on many parameters: on the target surface (upper tier of plants or lower), on the water rate (50, 100, 300 liters), on the processing speed, and even on weather conditions.

In this case, you need to pay attention to the air temperature, but also a very important parameter is the relative humidity of the air.

For example, at 20 degrees Celsius, a 100 micron drop at 40% humidity will "live" for only 10 seconds, after which it will evaporate. At the same time, the same drop at 30 degrees Celsius and 70% humidity will live for 20 seconds. That is, when choosing a nozzle, it is necessary to take into account not only the temperature and wind speed, but also the relative humidity of the air - this is a very important parameter.

Why is it important to choose the right injector?

If we consider all the costs of field treatment (depreciation of the machine, the cost of solutions, the cost of fuel, the salary of workers), then the cost of the nozzle will be only one percent of all costs for the treatment of fields with fertilizers or pesticides. Therefore, using the right and high-quality nozzles for sprayers is very beneficial. And it is not very profitable to save on injectors.

Types of nozzles for sprayers

You can define the main types of devices:

- - atomizer with a flat fan spray beam (normal, standard slotted). With its help, extremely fine spraying occurs, an increased tendency to drift drops is observed. The working pressure in this case is about 20-60 psi (this is 1.36-4.08 atmospheres);

- - equipped with a limiter at the outlet (deflector) - it provides a reduction in droplet drift by 50%, it is effective for small volumes of liquids;

- - a low-pressure atomizer with air blowing (injector slotted compact type IDK). Such products provide a noticeable reduction in droplet drift by 50-70%. They operate effectively at pressures up to 30-60 psi (2.04-4.08 atmospheres) or higher, while the fluid flow rate is about 47.5 l / ha;

- - high-pressure jet blower (injector slot, type ID) - allows you to minimize the carryover of drops (by 50-90%), they can be operated at pressures up to 60-80 psi (4.08-5.44 atmospheres) or even more , consumption of solutions is about 66 l/ha.

injection nozzles

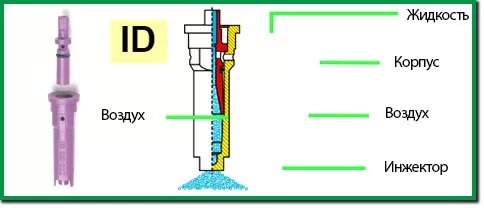

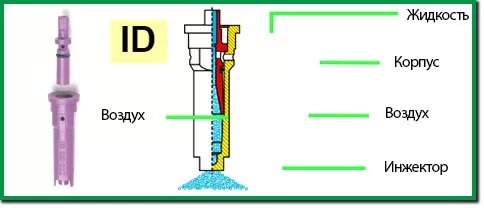

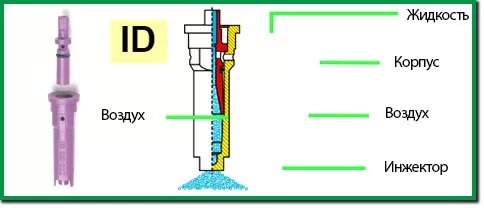

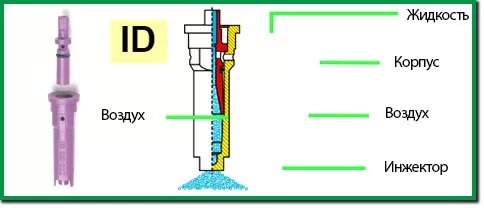

To imagine the operation of such nozzles, consider the scheme.

On it, we see that the liquid passes from above through the dispenser, then through the injector, which increases in diameter and due to this, the pressure decreases. Here air is sucked in, the liquid mixes with it and coarse droplets are formed, which have sufficient kinetic energy to fly as quickly as possible the distance between the rod and the target surface. In contrast to conventional slotted injectors, the liquid passes through the holes and is distributed on the mouthpiece.

If a plastic injection nozzle is recommended to be checked after an average of 60 hours of operation, then a simple slotted nozzle will come to its wear limits 2 times faster.

Nozzle selection based on sprayer types and farm sizes

If you divide these devices into 3 categories, you get: slotted, long injector and compact injector nozzles. Slit nozzles are suitable for small farms that own no more than 10 hectares.

Compact or long injector nozzle? Here you need to choose based on what maximum pressure the pump can deliver. If we are talking about 4 bar maximum, then you need to look towards the compact injection nozzle, which operates at a maximum pressure of 1 to 3 bar.

If there is wind less than 3 ms, we can increase the pressure from 4 to 5 bar.

We have a diaphragm-piston pump that produces 8 bar, then you can safely use long injector nozzles.

If during the processing of crops we work at a speed of 12 km per hour, then it would be advisable to use compact injector nozzles. If you plan to resort to high-speed processing of crops, then long injector nozzles will be necessary for you.

Art-Agro offers a wide range of nozzles of different types from the best manufacturers. They can best match your sprayers, goals and needs. The right choice will provide economical consumption, a large processing area, and minimize possible harm to human health. Our managers are always ready to help and advise you. Contact us, we are always in touch.

Recommended products

How to choose and buy nozzles for sprayers? What nuances need to be taken into account? What types of nozzles are on the market? This is detailed in the article.

Why are injectors needed?

Agricultural sprayers are primarily used for precise spraying of water, necessary biological products and various solutions for pest, disease, weed control or plant nutrition.

In order for the solutions to accurately hit the desired surfaces and to save the amount of liquid, special devices were invented - nozzles.

During operation, the solution passes through the body of the nozzle, is sent to a special reservoir, where it is saturated with air. Weighted droplets are not blown away so quickly by the wind, falling on the planned area of green spaces. This significantly increases the efficiency of crop treatment, there is no need to additionally increase the concentration of chemical solutions or re-treat the plants.

Spray nozzles - types

Before purchasing the nozzles you need, you need to understand their types. Based on the design, they are divided by the number of heads:

- - single;

- - triple;

- - quadruple;

- - five.

Happen with one or two exits for connection to system. The atomizer itself at the nozzle can also be equipped with an applicator, for greater savings.

The so-called injector nozzles equipped with air blowing are best suited for large volumes. Experts recommend purchasing them for cars with large tanks. Then it becomes possible to work longer in the field, not to return to the gas station again.

How to choose nozzles

The point of spraying is to ensure that everything we pour into the tank hits the target surface.

Nozzles, like various other parts of the sprayer, it is important to select based on the type and model of the unit. The correct choice will significantly affect the overall efficiency of your equipment. The choice of nozzles depends on many parameters: on the target surface (upper tier of plants or lower), on the water rate (50, 100, 300 liters), on the processing speed, and even on weather conditions.

In this case, you need to pay attention to the air temperature, but also a very important parameter is the relative humidity of the air.

For example, at 20 degrees Celsius, a 100 micron drop at 40% humidity will "live" for only 10 seconds, after which it will evaporate. At the same time, the same drop at 30 degrees Celsius and 70% humidity will live for 20 seconds. That is, when choosing a nozzle, it is necessary to take into account not only the temperature and wind speed, but also the relative humidity of the air - this is a very important parameter.

Why is it important to choose the right injector?

If we consider all the costs of field treatment (depreciation of the machine, the cost of solutions, the cost of fuel, the salary of workers), then the cost of the nozzle will be only one percent of all costs for the treatment of fields with fertilizers or pesticides. Therefore, using the right and high-quality nozzles for sprayers is very beneficial. And it is not very profitable to save on injectors.

Types of nozzles for sprayers

You can define the main types of devices:

- - atomizer with a flat fan spray beam (normal, standard slotted). With its help, extremely fine spraying occurs, an increased tendency to drift drops is observed. The working pressure in this case is about 20-60 psi (this is 1.36-4.08 atmospheres);

- - equipped with a limiter at the outlet (deflector) - it provides a reduction in droplet drift by 50%, it is effective for small volumes of liquids;

- - a low-pressure atomizer with air blowing (injector slotted compact type IDK). Such products provide a noticeable reduction in droplet drift by 50-70%. They operate effectively at pressures up to 30-60 psi (2.04-4.08 atmospheres) or higher, while the fluid flow rate is about 47.5 l / ha;

- - high-pressure jet blower (injector slot, type ID) - allows you to minimize the carryover of drops (by 50-90%), they can be operated at pressures up to 60-80 psi (4.08-5.44 atmospheres) or even more , consumption of solutions is about 66 l/ha.

injection nozzles

To imagine the operation of such nozzles, consider the scheme.

On it, we see that the liquid passes from above through the dispenser, then through the injector, which increases in diameter and due to this, the pressure decreases. Here air is sucked in, the liquid mixes with it and coarse droplets are formed, which have sufficient kinetic energy to fly as quickly as possible the distance between the rod and the target surface. In contrast to conventional slotted injectors, the liquid passes through the holes and is distributed on the mouthpiece.

If a plastic injection nozzle is recommended to be checked after an average of 60 hours of operation, then a simple slotted nozzle will come to its wear limits 2 times faster.

Nozzle selection based on sprayer types and farm sizes

If you divide these devices into 3 categories, you get: slotted, long injector and compact injector nozzles. Slit nozzles are suitable for small farms that own no more than 10 hectares.

Compact or long injector nozzle? Here you need to choose based on what maximum pressure the pump can deliver. If we are talking about 4 bar maximum, then you need to look towards the compact injection nozzle, which operates at a maximum pressure of 1 to 3 bar.

If there is wind less than 3 ms, we can increase the pressure from 4 to 5 bar.

We have a diaphragm-piston pump that produces 8 bar, then you can safely use long injector nozzles.

If during the processing of crops we work at a speed of 12 km per hour, then it would be advisable to use compact injector nozzles. If you plan to resort to high-speed processing of crops, then long injector nozzles will be necessary for you.

Art-Agro offers a wide range of nozzles of different types from the best manufacturers. They can best match your sprayers, goals and needs. The right choice will provide economical consumption, a large processing area, and minimize possible harm to human health. Our managers are always ready to help and advise you. Contact us, we are always in touch.

How to choose and buy nozzles for sprayers? What nuances need to be taken into account? What types of nozzles are on the market? This is detailed in the article.

Why are injectors needed?

Agricultural sprayers are primarily used for precise spraying of water, necessary biological products and various solutions for pest, disease, weed control or plant nutrition.

In order for the solutions to accurately hit the desired surfaces and to save the amount of liquid, special devices were invented - nozzles.

During operation, the solution passes through the body of the nozzle, is sent to a special reservoir, where it is saturated with air. Weighted droplets are not blown away so quickly by the wind, falling on the planned area of green spaces. This significantly increases the efficiency of crop treatment, there is no need to additionally increase the concentration of chemical solutions or re-treat the plants.

Spray nozzles - types

Before purchasing the nozzles you need, you need to understand their types. Based on the design, they are divided by the number of heads:

- - single;

- - triple;

- - quadruple;

- - five.

Happen with one or two exits for connection to system. The atomizer itself at the nozzle can also be equipped with an applicator, for greater savings.

The so-called injector nozzles equipped with air blowing are best suited for large volumes. Experts recommend purchasing them for cars with large tanks. Then it becomes possible to work longer in the field, not to return to the gas station again.

How to choose nozzles

The point of spraying is to ensure that everything we pour into the tank hits the target surface.

Nozzles, like various other parts of the sprayer, it is important to select based on the type and model of the unit. The correct choice will significantly affect the overall efficiency of your equipment. The choice of nozzles depends on many parameters: on the target surface (upper tier of plants or lower), on the water rate (50, 100, 300 liters), on the processing speed, and even on weather conditions.

In this case, you need to pay attention to the air temperature, but also a very important parameter is the relative humidity of the air.

For example, at 20 degrees Celsius, a 100 micron drop at 40% humidity will "live" for only 10 seconds, after which it will evaporate. At the same time, the same drop at 30 degrees Celsius and 70% humidity will live for 20 seconds. That is, when choosing a nozzle, it is necessary to take into account not only the temperature and wind speed, but also the relative humidity of the air - this is a very important parameter.

Why is it important to choose the right injector?

If we consider all the costs of field treatment (depreciation of the machine, the cost of solutions, the cost of fuel, the salary of workers), then the cost of the nozzle will be only one percent of all costs for the treatment of fields with fertilizers or pesticides. Therefore, using the right and high-quality nozzles for sprayers is very beneficial. And it is not very profitable to save on injectors.

Types of nozzles for sprayers

You can define the main types of devices:

- - atomizer with a flat fan spray beam (normal, standard slotted). With its help, extremely fine spraying occurs, an increased tendency to drift drops is observed. The working pressure in this case is about 20-60 psi (this is 1.36-4.08 atmospheres);

- - equipped with a limiter at the outlet (deflector) - it provides a reduction in droplet drift by 50%, it is effective for small volumes of liquids;

- - a low-pressure atomizer with air blowing (injector slotted compact type IDK). Such products provide a noticeable reduction in droplet drift by 50-70%. They operate effectively at pressures up to 30-60 psi (2.04-4.08 atmospheres) or higher, while the fluid flow rate is about 47.5 l / ha;

- - high-pressure jet blower (injector slot, type ID) - allows you to minimize the carryover of drops (by 50-90%), they can be operated at pressures up to 60-80 psi (4.08-5.44 atmospheres) or even more , consumption of solutions is about 66 l/ha.

injection nozzles

To imagine the operation of such nozzles, consider the scheme.

On it, we see that the liquid passes from above through the dispenser, then through the injector, which increases in diameter and due to this, the pressure decreases. Here air is sucked in, the liquid mixes with it and coarse droplets are formed, which have sufficient kinetic energy to fly as quickly as possible the distance between the rod and the target surface. In contrast to conventional slotted injectors, the liquid passes through the holes and is distributed on the mouthpiece.

If a plastic injection nozzle is recommended to be checked after an average of 60 hours of operation, then a simple slotted nozzle will come to its wear limits 2 times faster.

Nozzle selection based on sprayer types and farm sizes

If you divide these devices into 3 categories, you get: slotted, long injector and compact injector nozzles. Slit nozzles are suitable for small farms that own no more than 10 hectares.

Compact or long injector nozzle? Here you need to choose based on what maximum pressure the pump can deliver. If we are talking about 4 bar maximum, then you need to look towards the compact injection nozzle, which operates at a maximum pressure of 1 to 3 bar.

If there is wind less than 3 ms, we can increase the pressure from 4 to 5 bar.

We have a diaphragm-piston pump that produces 8 bar, then you can safely use long injector nozzles.

If during the processing of crops we work at a speed of 12 km per hour, then it would be advisable to use compact injector nozzles. If you plan to resort to high-speed processing of crops, then long injector nozzles will be necessary for you.

Art-Agro offers a wide range of nozzles of different types from the best manufacturers. They can best match your sprayers, goals and needs. The right choice will provide economical consumption, a large processing area, and minimize possible harm to human health. Our managers are always ready to help and advise you. Contact us, we are always in touch.

How to choose and buy nozzles for sprayers? What nuances need to be taken into account? What types of nozzles are on the market? This is detailed in the article.

Why are injectors needed?

Agricultural sprayers are primarily used for precise spraying of water, necessary biological products and various solutions for pest, disease, weed control or plant nutrition.

In order for the solutions to accurately hit the desired surfaces and to save the amount of liquid, special devices were invented - nozzles.

During operation, the solution passes through the body of the nozzle, is sent to a special reservoir, where it is saturated with air. Weighted droplets are not blown away so quickly by the wind, falling on the planned area of green spaces. This significantly increases the efficiency of crop treatment, there is no need to additionally increase the concentration of chemical solutions or re-treat the plants.

Spray nozzles - types

Before purchasing the nozzles you need, you need to understand their types. Based on the design, they are divided by the number of heads:

- - single;

- - triple;

- - quadruple;

- - five.

Happen with one or two exits for connection to system. The atomizer itself at the nozzle can also be equipped with an applicator, for greater savings.

The so-called injector nozzles equipped with air blowing are best suited for large volumes. Experts recommend purchasing them for cars with large tanks. Then it becomes possible to work longer in the field, not to return to the gas station again.

How to choose nozzles

The point of spraying is to ensure that everything we pour into the tank hits the target surface.

Nozzles, like various other parts of the sprayer, it is important to select based on the type and model of the unit. The correct choice will significantly affect the overall efficiency of your equipment. The choice of nozzles depends on many parameters: on the target surface (upper tier of plants or lower), on the water rate (50, 100, 300 liters), on the processing speed, and even on weather conditions.

In this case, you need to pay attention to the air temperature, but also a very important parameter is the relative humidity of the air.

For example, at 20 degrees Celsius, a 100 micron drop at 40% humidity will "live" for only 10 seconds, after which it will evaporate. At the same time, the same drop at 30 degrees Celsius and 70% humidity will live for 20 seconds. That is, when choosing a nozzle, it is necessary to take into account not only the temperature and wind speed, but also the relative humidity of the air - this is a very important parameter.

Why is it important to choose the right injector?

If we consider all the costs of field treatment (depreciation of the machine, the cost of solutions, the cost of fuel, the salary of workers), then the cost of the nozzle will be only one percent of all costs for the treatment of fields with fertilizers or pesticides. Therefore, using the right and high-quality nozzles for sprayers is very beneficial. And it is not very profitable to save on injectors.

Types of nozzles for sprayers

You can define the main types of devices:

- - atomizer with a flat fan spray beam (normal, standard slotted). With its help, extremely fine spraying occurs, an increased tendency to drift drops is observed. The working pressure in this case is about 20-60 psi (this is 1.36-4.08 atmospheres);

- - equipped with a limiter at the outlet (deflector) - it provides a reduction in droplet drift by 50%, it is effective for small volumes of liquids;

- - a low-pressure atomizer with air blowing (injector slotted compact type IDK). Such products provide a noticeable reduction in droplet drift by 50-70%. They operate effectively at pressures up to 30-60 psi (2.04-4.08 atmospheres) or higher, while the fluid flow rate is about 47.5 l / ha;

- - high-pressure jet blower (injector slot, type ID) - allows you to minimize the carryover of drops (by 50-90%), they can be operated at pressures up to 60-80 psi (4.08-5.44 atmospheres) or even more , consumption of solutions is about 66 l/ha.

injection nozzles

To imagine the operation of such nozzles, consider the scheme.

On it, we see that the liquid passes from above through the dispenser, then through the injector, which increases in diameter and due to this, the pressure decreases. Here air is sucked in, the liquid mixes with it and coarse droplets are formed, which have sufficient kinetic energy to fly as quickly as possible the distance between the rod and the target surface. In contrast to conventional slotted injectors, the liquid passes through the holes and is distributed on the mouthpiece.

If a plastic injection nozzle is recommended to be checked after an average of 60 hours of operation, then a simple slotted nozzle will come to its wear limits 2 times faster.

Nozzle selection based on sprayer types and farm sizes

If you divide these devices into 3 categories, you get: slotted, long injector and compact injector nozzles. Slit nozzles are suitable for small farms that own no more than 10 hectares.

Compact or long injector nozzle? Here you need to choose based on what maximum pressure the pump can deliver. If we are talking about 4 bar maximum, then you need to look towards the compact injection nozzle, which operates at a maximum pressure of 1 to 3 bar.

If there is wind less than 3 ms, we can increase the pressure from 4 to 5 bar.

We have a diaphragm-piston pump that produces 8 bar, then you can safely use long injector nozzles.

If during the processing of crops we work at a speed of 12 km per hour, then it would be advisable to use compact injector nozzles. If you plan to resort to high-speed processing of crops, then long injector nozzles will be necessary for you.

Art-Agro offers a wide range of nozzles of different types from the best manufacturers. They can best match your sprayers, goals and needs. The right choice will provide economical consumption, a large processing area, and minimize possible harm to human health. Our managers are always ready to help and advise you. Contact us, we are always in touch.