What is the John Deere grain loss sensor for?

01/11/2025

John Deere grain loss sensor - why is it needed and how to understand that it is defective

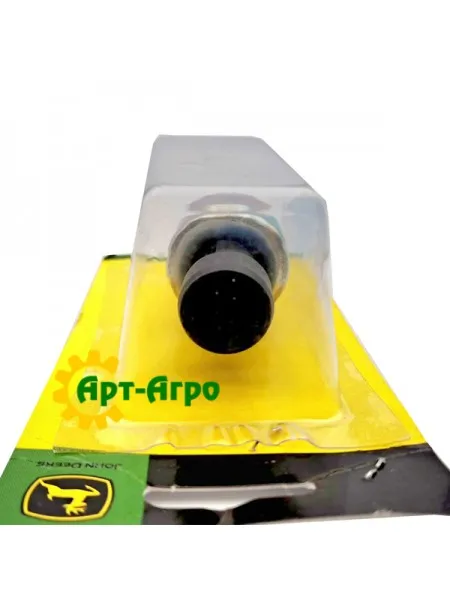

The grain loss sensor is an important element of the John Deere harvester control system. Its main function is to monitor the amount of grain lost during threshing or cleaning and to transmit the data to the operator on the display.

This allows you to control the level of losses in real time and adjust the settings of the combine — fan speed, drum clearance, movement speed, etc. The result is less crop loss and higher harvesting efficiency.

How the grain loss sensor works

The sensor is installed in the rear of the combine, most often under the straw shaker or in the cleaning system. When the grain hits the surface of the sensor, it fixes the pulses and sends a signal to the electronic control unit.

The controller processes the data and shows the operator the level of losses. If the readings exceed the norm, it is necessary to correct the parameters of the machine.

Signs of malfunction

- On the screen there is a constant zero or maximum losses, regardless of the conditions.

- An error on the Combine Advisor or GreenStar monitor.

- Damaged cable or connector, corrosion of contacts.

- The sensor is contaminated with dust or straw.

Checking the sensor

- Turn off the combine and disconnect the cable.

- Check the case - there should be no cracks.

- Check the wiring with a multimeter.

- If the data is still incorrect, replace the sensor.

Where to buy

Original and analog John Deere grain loss sensors are available in the online store

Art-Agro - verified spare parts, fast delivery and assistance in selection by article.

Recommended products

John Deere grain loss sensor - why is it needed and how to understand that it is defective

The grain loss sensor is an important element of the John Deere harvester control system. Its main function is to monitor the amount of grain lost during threshing or cleaning and to transmit the data to the operator on the display.

This allows you to control the level of losses in real time and adjust the settings of the combine — fan speed, drum clearance, movement speed, etc. The result is less crop loss and higher harvesting efficiency.

How the grain loss sensor works

The sensor is installed in the rear of the combine, most often under the straw shaker or in the cleaning system. When the grain hits the surface of the sensor, it fixes the pulses and sends a signal to the electronic control unit.

The controller processes the data and shows the operator the level of losses. If the readings exceed the norm, it is necessary to correct the parameters of the machine.

Signs of malfunction

- On the screen there is a constant zero or maximum losses, regardless of the conditions.

- An error on the Combine Advisor or GreenStar monitor.

- Damaged cable or connector, corrosion of contacts.

- The sensor is contaminated with dust or straw.

Checking the sensor

- Turn off the combine and disconnect the cable.

- Check the case - there should be no cracks.

- Check the wiring with a multimeter.

- If the data is still incorrect, replace the sensor.

Where to buy

Original and analog John Deere grain loss sensors are available in the online store

Art-Agro - verified spare parts, fast delivery and assistance in selection by article.

John Deere grain loss sensor - why is it needed and how to understand that it is defective

The grain loss sensor is an important element of the John Deere harvester control system. Its main function is to monitor the amount of grain lost during threshing or cleaning and to transmit the data to the operator on the display.

This allows you to control the level of losses in real time and adjust the settings of the combine — fan speed, drum clearance, movement speed, etc. The result is less crop loss and higher harvesting efficiency.

How the grain loss sensor works

The sensor is installed in the rear of the combine, most often under the straw shaker or in the cleaning system. When the grain hits the surface of the sensor, it fixes the pulses and sends a signal to the electronic control unit.

The controller processes the data and shows the operator the level of losses. If the readings exceed the norm, it is necessary to correct the parameters of the machine.

Signs of malfunction

- On the screen there is a constant zero or maximum losses, regardless of the conditions.

- An error on the Combine Advisor or GreenStar monitor.

- Damaged cable or connector, corrosion of contacts.

- The sensor is contaminated with dust or straw.

Checking the sensor

- Turn off the combine and disconnect the cable.

- Check the case - there should be no cracks.

- Check the wiring with a multimeter.

- If the data is still incorrect, replace the sensor.

Where to buy

Original and analog John Deere grain loss sensors are available in the online store

Art-Agro - verified spare parts, fast delivery and assistance in selection by article.

John Deere grain loss sensor - why is it needed and how to understand that it is defective

The grain loss sensor is an important element of the John Deere harvester control system. Its main function is to monitor the amount of grain lost during threshing or cleaning and to transmit the data to the operator on the display.

This allows you to control the level of losses in real time and adjust the settings of the combine — fan speed, drum clearance, movement speed, etc. The result is less crop loss and higher harvesting efficiency.

How the grain loss sensor works

The sensor is installed in the rear of the combine, most often under the straw shaker or in the cleaning system. When the grain hits the surface of the sensor, it fixes the pulses and sends a signal to the electronic control unit.

The controller processes the data and shows the operator the level of losses. If the readings exceed the norm, it is necessary to correct the parameters of the machine.

Signs of malfunction

- On the screen there is a constant zero or maximum losses, regardless of the conditions.

- An error on the Combine Advisor or GreenStar monitor.

- Damaged cable or connector, corrosion of contacts.

- The sensor is contaminated with dust or straw.

Checking the sensor

- Turn off the combine and disconnect the cable.

- Check the case - there should be no cracks.

- Check the wiring with a multimeter.

- If the data is still incorrect, replace the sensor.

Where to buy

Original and analog John Deere grain loss sensors are available in the online store

Art-Agro - verified spare parts, fast delivery and assistance in selection by article.

John Deere grain loss sensor - why is it needed and how to understand that it is defective

The grain loss sensor is an important element of the John Deere harvester control system. Its main function is to monitor the amount of grain lost during threshing or cleaning and to transmit the data to the operator on the display.

This allows you to control the level of losses in real time and adjust the settings of the combine — fan speed, drum clearance, movement speed, etc. The result is less crop loss and higher harvesting efficiency.

How the grain loss sensor works

The sensor is installed in the rear of the combine, most often under the straw shaker or in the cleaning system. When the grain hits the surface of the sensor, it fixes the pulses and sends a signal to the electronic control unit.

The controller processes the data and shows the operator the level of losses. If the readings exceed the norm, it is necessary to correct the parameters of the machine.

Signs of malfunction

- On the screen there is a constant zero or maximum losses, regardless of the conditions.

- An error on the Combine Advisor or GreenStar monitor.

- Damaged cable or connector, corrosion of contacts.

- The sensor is contaminated with dust or straw.

Checking the sensor

- Turn off the combine and disconnect the cable.

- Check the case - there should be no cracks.

- Check the wiring with a multimeter.

- If the data is still incorrect, replace the sensor.

Where to buy

Original and analog John Deere grain loss sensors are available in the online store

Art-Agro - verified spare parts, fast delivery and assistance in selection by article.

John Deere grain loss sensor - why is it needed and how to understand that it is defective

The grain loss sensor is an important element of the John Deere harvester control system. Its main function is to monitor the amount of grain lost during threshing or cleaning and to transmit the data to the operator on the display.

This allows you to control the level of losses in real time and adjust the settings of the combine — fan speed, drum clearance, movement speed, etc. The result is less crop loss and higher harvesting efficiency.

How the grain loss sensor works

The sensor is installed in the rear of the combine, most often under the straw shaker or in the cleaning system. When the grain hits the surface of the sensor, it fixes the pulses and sends a signal to the electronic control unit.

The controller processes the data and shows the operator the level of losses. If the readings exceed the norm, it is necessary to correct the parameters of the machine.

Signs of malfunction

- On the screen there is a constant zero or maximum losses, regardless of the conditions.

- An error on the Combine Advisor or GreenStar monitor.

- Damaged cable or connector, corrosion of contacts.

- The sensor is contaminated with dust or straw.

Checking the sensor

- Turn off the combine and disconnect the cable.

- Check the case - there should be no cracks.

- Check the wiring with a multimeter.

- If the data is still incorrect, replace the sensor.

Where to buy

Original and analog John Deere grain loss sensors are available in the online store

Art-Agro - verified spare parts, fast delivery and assistance in selection by article.

John Deere grain loss sensor - why is it needed and how to understand that it is defective

The grain loss sensor is an important element of the John Deere harvester control system. Its main function is to monitor the amount of grain lost during threshing or cleaning and to transmit the data to the operator on the display.

This allows you to control the level of losses in real time and adjust the settings of the combine — fan speed, drum clearance, movement speed, etc. The result is less crop loss and higher harvesting efficiency.

How the grain loss sensor works

The sensor is installed in the rear of the combine, most often under the straw shaker or in the cleaning system. When the grain hits the surface of the sensor, it fixes the pulses and sends a signal to the electronic control unit.

The controller processes the data and shows the operator the level of losses. If the readings exceed the norm, it is necessary to correct the parameters of the machine.

Signs of malfunction

- On the screen there is a constant zero or maximum losses, regardless of the conditions.

- An error on the Combine Advisor or GreenStar monitor.

- Damaged cable or connector, corrosion of contacts.

- The sensor is contaminated with dust or straw.

Checking the sensor

- Turn off the combine and disconnect the cable.

- Check the case - there should be no cracks.

- Check the wiring with a multimeter.

- If the data is still incorrect, replace the sensor.

Where to buy

Original and analog John Deere grain loss sensors are available in the online store

Art-Agro - verified spare parts, fast delivery and assistance in selection by article.

John Deere grain loss sensor - why is it needed and how to understand that it is defective

The grain loss sensor is an important element of the John Deere harvester control system. Its main function is to monitor the amount of grain lost during threshing or cleaning and to transmit the data to the operator on the display.

This allows you to control the level of losses in real time and adjust the settings of the combine — fan speed, drum clearance, movement speed, etc. The result is less crop loss and higher harvesting efficiency.

How the grain loss sensor works

The sensor is installed in the rear of the combine, most often under the straw shaker or in the cleaning system. When the grain hits the surface of the sensor, it fixes the pulses and sends a signal to the electronic control unit.

The controller processes the data and shows the operator the level of losses. If the readings exceed the norm, it is necessary to correct the parameters of the machine.

Signs of malfunction

- On the screen there is a constant zero or maximum losses, regardless of the conditions.

- An error on the Combine Advisor or GreenStar monitor.

- Damaged cable or connector, corrosion of contacts.

- The sensor is contaminated with dust or straw.

Checking the sensor

- Turn off the combine and disconnect the cable.

- Check the case - there should be no cracks.

- Check the wiring with a multimeter.

- If the data is still incorrect, replace the sensor.

Where to buy

Original and analog John Deere grain loss sensors are available in the online store

Art-Agro - verified spare parts, fast delivery and assistance in selection by article.

John Deere grain loss sensor - why is it needed and how to understand that it is defective

The grain loss sensor is an important element of the John Deere harvester control system. Its main function is to monitor the amount of grain lost during threshing or cleaning and to transmit the data to the operator on the display.

This allows you to control the level of losses in real time and adjust the settings of the combine — fan speed, drum clearance, movement speed, etc. The result is less crop loss and higher harvesting efficiency.

How the grain loss sensor works

The sensor is installed in the rear of the combine, most often under the straw shaker or in the cleaning system. When the grain hits the surface of the sensor, it fixes the pulses and sends a signal to the electronic control unit.

The controller processes the data and shows the operator the level of losses. If the readings exceed the norm, it is necessary to correct the parameters of the machine.

Signs of malfunction

- On the screen there is a constant zero or maximum losses, regardless of the conditions.

- An error on the Combine Advisor or GreenStar monitor.

- Damaged cable or connector, corrosion of contacts.

- The sensor is contaminated with dust or straw.

Checking the sensor

- Turn off the combine and disconnect the cable.

- Check the case - there should be no cracks.

- Check the wiring with a multimeter.

- If the data is still incorrect, replace the sensor.

Where to buy

Original and analog John Deere grain loss sensors are available in the online store

Art-Agro - verified spare parts, fast delivery and assistance in selection by article.

John Deere grain loss sensor - why is it needed and how to understand that it is defective

The grain loss sensor is an important element of the John Deere harvester control system. Its main function is to monitor the amount of grain lost during threshing or cleaning and to transmit the data to the operator on the display.

This allows you to control the level of losses in real time and adjust the settings of the combine — fan speed, drum clearance, movement speed, etc. The result is less crop loss and higher harvesting efficiency.

How the grain loss sensor works

The sensor is installed in the rear of the combine, most often under the straw shaker or in the cleaning system. When the grain hits the surface of the sensor, it fixes the pulses and sends a signal to the electronic control unit.

The controller processes the data and shows the operator the level of losses. If the readings exceed the norm, it is necessary to correct the parameters of the machine.

Signs of malfunction

- On the screen there is a constant zero or maximum losses, regardless of the conditions.

- An error on the Combine Advisor or GreenStar monitor.

- Damaged cable or connector, corrosion of contacts.

- The sensor is contaminated with dust or straw.

Checking the sensor

- Turn off the combine and disconnect the cable.

- Check the case - there should be no cracks.

- Check the wiring with a multimeter.

- If the data is still incorrect, replace the sensor.

Where to buy

Original and analog John Deere grain loss sensors are available in the online store

Art-Agro - verified spare parts, fast delivery and assistance in selection by article.

John Deere grain loss sensor - why is it needed and how to understand that it is defective

The grain loss sensor is an important element of the John Deere harvester control system. Its main function is to monitor the amount of grain lost during threshing or cleaning and to transmit the data to the operator on the display.

This allows you to control the level of losses in real time and adjust the settings of the combine — fan speed, drum clearance, movement speed, etc. The result is less crop loss and higher harvesting efficiency.

How the grain loss sensor works

The sensor is installed in the rear of the combine, most often under the straw shaker or in the cleaning system. When the grain hits the surface of the sensor, it fixes the pulses and sends a signal to the electronic control unit.

The controller processes the data and shows the operator the level of losses. If the readings exceed the norm, it is necessary to correct the parameters of the machine.

Signs of malfunction

- On the screen there is a constant zero or maximum losses, regardless of the conditions.

- An error on the Combine Advisor or GreenStar monitor.

- Damaged cable or connector, corrosion of contacts.

- The sensor is contaminated with dust or straw.

Checking the sensor

- Turn off the combine and disconnect the cable.

- Check the case - there should be no cracks.

- Check the wiring with a multimeter.

- If the data is still incorrect, replace the sensor.

Where to buy

Original and analog John Deere grain loss sensors are available in the online store

Art-Agro - verified spare parts, fast delivery and assistance in selection by article.

John Deere grain loss sensor - why is it needed and how to understand that it is defective

The grain loss sensor is an important element of the John Deere harvester control system. Its main function is to monitor the amount of grain lost during threshing or cleaning and to transmit the data to the operator on the display.

This allows you to control the level of losses in real time and adjust the settings of the combine — fan speed, drum clearance, movement speed, etc. The result is less crop loss and higher harvesting efficiency.

How the grain loss sensor works

The sensor is installed in the rear of the combine, most often under the straw shaker or in the cleaning system. When the grain hits the surface of the sensor, it fixes the pulses and sends a signal to the electronic control unit.

The controller processes the data and shows the operator the level of losses. If the readings exceed the norm, it is necessary to correct the parameters of the machine.

Signs of malfunction

- On the screen there is a constant zero or maximum losses, regardless of the conditions.

- An error on the Combine Advisor or GreenStar monitor.

- Damaged cable or connector, corrosion of contacts.

- The sensor is contaminated with dust or straw.

Checking the sensor

- Turn off the combine and disconnect the cable.

- Check the case - there should be no cracks.

- Check the wiring with a multimeter.

- If the data is still incorrect, replace the sensor.

Where to buy

Original and analog John Deere grain loss sensors are available in the online store

Art-Agro - verified spare parts, fast delivery and assistance in selection by article.

John Deere grain loss sensor - why is it needed and how to understand that it is defective

The grain loss sensor is an important element of the John Deere harvester control system. Its main function is to monitor the amount of grain lost during threshing or cleaning and to transmit the data to the operator on the display.

This allows you to control the level of losses in real time and adjust the settings of the combine — fan speed, drum clearance, movement speed, etc. The result is less crop loss and higher harvesting efficiency.

How the grain loss sensor works

The sensor is installed in the rear of the combine, most often under the straw shaker or in the cleaning system. When the grain hits the surface of the sensor, it fixes the pulses and sends a signal to the electronic control unit.

The controller processes the data and shows the operator the level of losses. If the readings exceed the norm, it is necessary to correct the parameters of the machine.

Signs of malfunction

- On the screen there is a constant zero or maximum losses, regardless of the conditions.

- An error on the Combine Advisor or GreenStar monitor.

- Damaged cable or connector, corrosion of contacts.

- The sensor is contaminated with dust or straw.

Checking the sensor

- Turn off the combine and disconnect the cable.

- Check the case - there should be no cracks.

- Check the wiring with a multimeter.

- If the data is still incorrect, replace the sensor.

Where to buy

Original and analog John Deere grain loss sensors are available in the online store

Art-Agro - verified spare parts, fast delivery and assistance in selection by article.

John Deere grain loss sensor - why is it needed and how to understand that it is defective

The grain loss sensor is an important element of the John Deere harvester control system. Its main function is to monitor the amount of grain lost during threshing or cleaning and to transmit the data to the operator on the display.

This allows you to control the level of losses in real time and adjust the settings of the combine — fan speed, drum clearance, movement speed, etc. The result is less crop loss and higher harvesting efficiency.

How the grain loss sensor works

The sensor is installed in the rear of the combine, most often under the straw shaker or in the cleaning system. When the grain hits the surface of the sensor, it fixes the pulses and sends a signal to the electronic control unit.

The controller processes the data and shows the operator the level of losses. If the readings exceed the norm, it is necessary to correct the parameters of the machine.

Signs of malfunction

- On the screen there is a constant zero or maximum losses, regardless of the conditions.

- An error on the Combine Advisor or GreenStar monitor.

- Damaged cable or connector, corrosion of contacts.

- The sensor is contaminated with dust or straw.

Checking the sensor

- Turn off the combine and disconnect the cable.

- Check the case - there should be no cracks.

- Check the wiring with a multimeter.

- If the data is still incorrect, replace the sensor.

Where to buy

Original and analog John Deere grain loss sensors are available in the online store

Art-Agro - verified spare parts, fast delivery and assistance in selection by article.

John Deere grain loss sensor - why is it needed and how to understand that it is defective

The grain loss sensor is an important element of the John Deere harvester control system. Its main function is to monitor the amount of grain lost during threshing or cleaning and to transmit the data to the operator on the display.

This allows you to control the level of losses in real time and adjust the settings of the combine — fan speed, drum clearance, movement speed, etc. The result is less crop loss and higher harvesting efficiency.

How the grain loss sensor works

The sensor is installed in the rear of the combine, most often under the straw shaker or in the cleaning system. When the grain hits the surface of the sensor, it fixes the pulses and sends a signal to the electronic control unit.

The controller processes the data and shows the operator the level of losses. If the readings exceed the norm, it is necessary to correct the parameters of the machine.

Signs of malfunction

- On the screen there is a constant zero or maximum losses, regardless of the conditions.

- An error on the Combine Advisor or GreenStar monitor.

- Damaged cable or connector, corrosion of contacts.

- The sensor is contaminated with dust or straw.

Checking the sensor

- Turn off the combine and disconnect the cable.

- Check the case - there should be no cracks.

- Check the wiring with a multimeter.

- If the data is still incorrect, replace the sensor.

Where to buy

Original and analog John Deere grain loss sensors are available in the online store

Art-Agro - verified spare parts, fast delivery and assistance in selection by article.

John Deere grain loss sensor - why is it needed and how to understand that it is defective

The grain loss sensor is an important element of the John Deere harvester control system. Its main function is to monitor the amount of grain lost during threshing or cleaning and to transmit the data to the operator on the display.

This allows you to control the level of losses in real time and adjust the settings of the combine — fan speed, drum clearance, movement speed, etc. The result is less crop loss and higher harvesting efficiency.

How the grain loss sensor works

The sensor is installed in the rear of the combine, most often under the straw shaker or in the cleaning system. When the grain hits the surface of the sensor, it fixes the pulses and sends a signal to the electronic control unit.

The controller processes the data and shows the operator the level of losses. If the readings exceed the norm, it is necessary to correct the parameters of the machine.

Signs of malfunction

- On the screen there is a constant zero or maximum losses, regardless of the conditions.

- An error on the Combine Advisor or GreenStar monitor.

- Damaged cable or connector, corrosion of contacts.

- The sensor is contaminated with dust or straw.

Checking the sensor

- Turn off the combine and disconnect the cable.

- Check the case - there should be no cracks.

- Check the wiring with a multimeter.

- If the data is still incorrect, replace the sensor.

Where to buy

Original and analog John Deere grain loss sensors are available in the online store

Art-Agro - verified spare parts, fast delivery and assistance in selection by article.

John Deere grain loss sensor - why is it needed and how to understand that it is defective

The grain loss sensor is an important element of the John Deere harvester control system. Its main function is to monitor the amount of grain lost during threshing or cleaning and to transmit the data to the operator on the display.

This allows you to control the level of losses in real time and adjust the settings of the combine — fan speed, drum clearance, movement speed, etc. The result is less crop loss and higher harvesting efficiency.

How the grain loss sensor works

The sensor is installed in the rear of the combine, most often under the straw shaker or in the cleaning system. When the grain hits the surface of the sensor, it fixes the pulses and sends a signal to the electronic control unit.

The controller processes the data and shows the operator the level of losses. If the readings exceed the norm, it is necessary to correct the parameters of the machine.

Signs of malfunction

- On the screen there is a constant zero or maximum losses, regardless of the conditions.

- An error on the Combine Advisor or GreenStar monitor.

- Damaged cable or connector, corrosion of contacts.

- The sensor is contaminated with dust or straw.

Checking the sensor

- Turn off the combine and disconnect the cable.

- Check the case - there should be no cracks.

- Check the wiring with a multimeter.

- If the data is still incorrect, replace the sensor.

Where to buy

Original and analog John Deere grain loss sensors are available in the online store

Art-Agro - verified spare parts, fast delivery and assistance in selection by article.